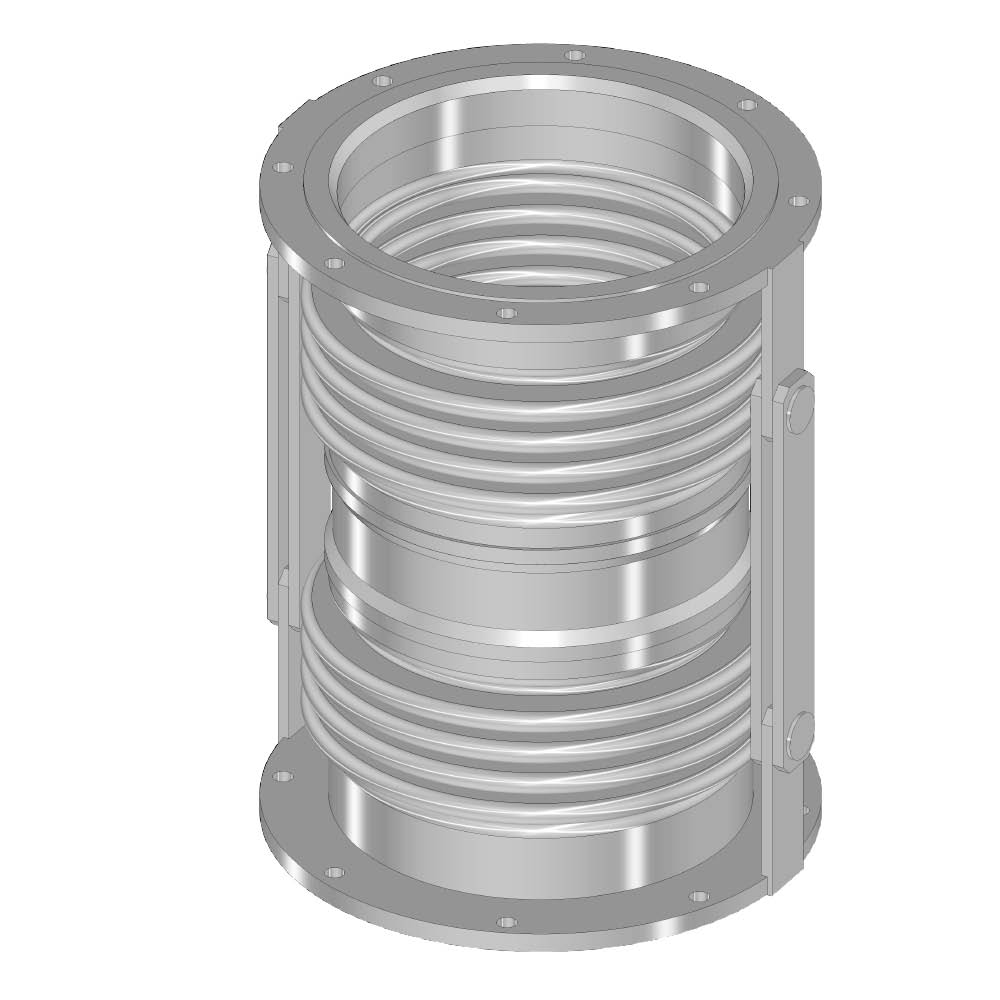

Double-hinged bellows, or Double-hinged expansion joints, are specialised components used in piping systems to accommodate large amounts of movement in one specific plane while restricting movement in other directions while maintaining the system’s structural integrity.

With their unique design, Hinged bellows are not your typical bellows. Like other bellows, they feature one or more convolutions made from thin-walled stainless steel tubing. However, what sets them apart is the incorporation of hinge mechanisms at specific points along the bellows. These hinges are the key to their functionality, allowing the bellows to flex and pivot in one direction while restricting movement in other directions. While significantly reducing forces on adjacent pipework and anchor points.

Stainless steel, a high-quality material, is the backbone of hinged bellows. Its excellent corrosion, durability, and temperature resistance make it the ideal choice for this application. The specific grade of stainless steel used is carefully selected based on factors such as the operating environment, temperature range, and compatibility with the conveyed fluid.

The design of stainless steel hinged bellows is a meticulous process that considers several factors to ensure optimal performance and reliability. These factors include the operating conditions, angular movement requirements, pressure rating, and end connections.

Stainless steel hinged bellows find application in various industries and systems where angular movement compensation is required, including:

The double-hinged design increases flexibility and movement capacity compared to single-hinged or unrestrained bellows. This increased flexibility enables the bellows to simultaneously accommodate more significant movements, including axial and lateral movements.

With their resistance to corrosion and robust construction, they offer a long service life backed by minimal maintenance requirements. This assurance of durability and longevity is a testament to the quality and reliability of hinged bellows. In summary, stainless steel hinged bellows are critical in accommodating angular movement in piping systems, providing flexibility, reliability, and longevity in diverse industrial applications.