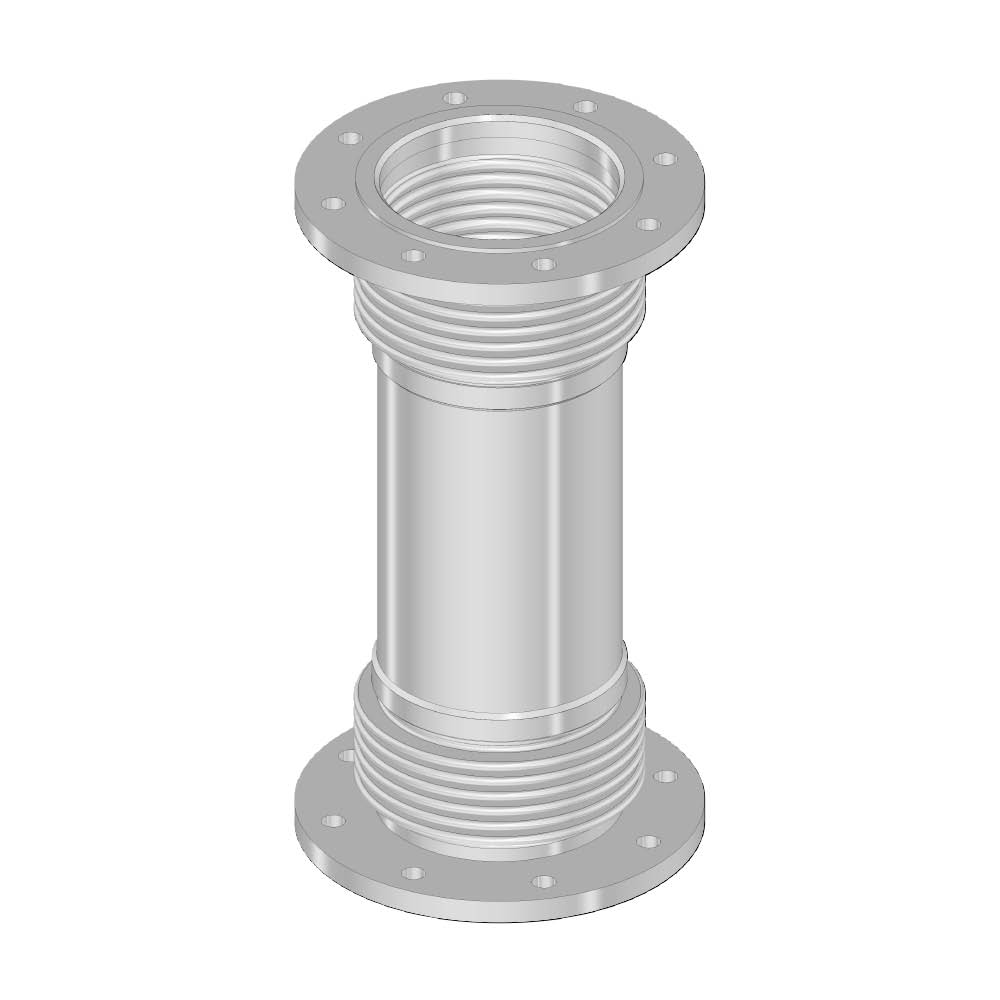

Double unrestrained steel bellows, with their unique design and construction, are specialised mechanical components that excel in managing thermal expansion, absorbing vibrations, and compensating for misalignment in industrial piping systems. This comprehensive guide provides an in-depth understanding of their unique features, uses, materials, design considerations, applications, and benefits.

Uses

We employ double unrestrained steel bellows in various industrial applications to:

- Manage Thermal Expansion: They absorb and compensate for the expansion and contraction of piping systems due to temperature changes.

- Absorb Vibrations: They reduce and dampen mechanical vibrations, protecting sensitive components and minimising noise.

- Accommodate Misalignment: They allow for slight misalignments between connected pipes or components, ensuring a secure and leak-free connection.

Construction

Double unrestrained steel bellows involve several key elements:

- Dual Bellows Configuration:

-

- Two Bellows Elements: The design includes two bellows elements connected in series, typically with a central pipe or spacer between them, providing enhanced flexibility and movement capacity.

-

- Convolutions: Each bellows element consists of multiple convolutions (corrugations), allowing the bellows to expand and contract effectively.

- Intermediate Pipe:

-

- The intermediate pipe separates the two bellows, maintaining the necessary distance for optimal movement and flexibility.

- End Connections:

-

- Flanges or Welding Ends: Depending on specific application requirements, the bellows’ can be fitted with flanges or prepared for welding.

Materials

We construct double unrestrained steel bellows from high-quality materials to ensure durability and performance under extreme conditions:

- Stainless Steel:

-

- Corrosion Resistance: Stainless steel has excellent resistance to corrosion and high temperatures.

-

- Grades: Various grades of stainless steel, such as 304, 316, and Inconel, are selected based on the application’s specific needs.

- Reinforcements:

-

- Protective Covers: External stainless steel covers protect against environmental factors.

Design Considerations

When designing double unrestrained steel bellows, we consider several critical factors:

- Movement Types:

-

- Axial Movement: Expansion and contraction along the length of the bellows.

-

- Lateral Movement: Side-to-side displacement.

-

- Angular Movement: Rotation around the axis of the bellows.

- Pressure and Temperature Ratings:

-

- Operating Conditions: We design the bellows to withstand the application’s specific pressure and temperature conditions.

-

- Safety Margins: We incorporate adequate safety margins to ensure reliable performance.

- Material Selection:

-

- Materials are chosen based on the conveyed media, environmental conditions, and required durability.

- End Fittings:

-

- The type of end fittings, such as flanges or welding ends, must be compatible with the existing piping system.

Applications

We use double unrestrained steel bellows in a wide range of industrial applications to accommodate large lateral movements:

- Industrial Ducting Systems:

-

- Ventilation and Exhaust: Transporting hot air, gases, or fumes in engines and turbines’ industrial ventilation and exhaust systems.

- Chemical and Petrochemical Industries:

-

- Hot Chemical Transport: Connecting pipelines carrying hot chemicals, solvents, or hazardous materials.

- Power Generation:

-

- High-Temperature Components: Connecting power plant boilers, turbines, and heat exchangers.

- Food and Pharmaceutical Processing:

-

- High-Heat Applications: Ensuring safe and efficient operation in high-temperature food processing and pharmaceutical manufacturing.

- Environmental Control Systems:

-

- Emission Control: Used in incineration plants and other systems to manage high temperatures and control emissions.

Benefits

Double unrestrained steel bellows offer several key benefits:

- Thermal Resistance:

-

- Depending on the material, they can withstand high temperatures, often up to 1000°C (1832°F) or more.

- Flexibility:

-

- They absorb thermal expansion, vibrations, and misalignment, protecting the integrity of the piping system.

- Durability:

-

- They ensure long-lasting performance using robust materials like stainless steel in harsh environments.

- Customisation:

-

- They are available in various sizes and configurations to meet specific application requirements.

- Safety:

-

- They ensure safe operation in high-temperature environments, reducing the risk of system failure or accidents.

Enhanced Capabilities with Flexible Connections

At Flexible Connections, we offer an extensive range of double unrestrained steel bellows tailored for various applications. Our products handle movements in all planes and attenuate noise and vibration, providing comprehensive solutions for your piping system needs.

Double unrestrained steel bellows are critical components for maintaining the integrity and efficiency of piping systems under extreme conditions. Their ability to accommodate significant movements, absorb vibrations, and withstand high temperatures makes them indispensable in numerous industrial applications.